Safety Shower

DESCRIPTION

A safety shower is a piece of equipment designed to wash

away chemicals that have come into contact with the skin or

clothing as the result of a chemical splash or spill.

They are also used to disinfect workers who have been

exposed to airborne chemicals or toxins.

APPLICATIONS

⇒ Emergency shower / Eye wash must be installed in places

that are easily visible and accessible, from atleast three

directions.

⇒Facilities or industries likely to require a safety shower and

eye wash station include:

⇒Oil and petroleum refineries

⇒Hazardous chemical storage facilities

⇒Battery charging facilities

⇒High-dust environments like grain elevators

⇒University and high-school laboratories

⇒Hazardous waste disposal areas

⇒Staff must be properly instructed/trained on how to

operate the Emergency shower / Eye wash Unit.

US-GI-1A - Wall Mounted Eye/Face wash

Pedestal unit include push plate which is laser cutted to operate

the ABS atomizer eye/face wash head, zero upward velocity

stream engineering with even aerated flow. ABS Atomizer is

equipped with flip-off cover to prevent dust contamination. 1⁄2”

inch brass ball valve, Impact corrosion resistant, with ABS

receptor bowl. Inlet supply connection is 1⁄2” and drain connection

is 1 1⁄4”. Hot dipped Galvanized stanchion as per IS 1239 with

epoxy color (green/red/yellow). Flange to support eye/face

wash unit having 4 holes of 10mm.

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg / 12ltr. Per

minute

CONFORMING TO IS: 10592- 1982 revised as per 2018

US-GI-1 - Eye/Face Wash Fountain Head

Pedestal unit include push plate which is laser cutted to operate

the ABS atomizer eye/face wash head, zero upward velocity

stream engineering with even aerated flow. ABS Atomizer is

equipped with flip-off cover to prevent dust contamination. 1⁄2”

inch brass ball valve, Impact corrosion resistant, with ABS

receptor bowl. Inlet supply connection is 1⁄2” and drain connection

is 1 1⁄4”. Hot dipped Galvanized stanchion as per IS 1239 with

epoxy color (green/red/yellow). Flange to support eye/face

wash unit having 4 holes of 10mm.

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg / 12ltr. Per

minute

CONFORMING TO IS: 10592- 1982 revised as per 2018

US-GI-2 - Eye/Face Wash Fountain Head with Foot Pedal

FOOT PEDAL unit include push plate which is laser cutted and

foot operated for the ABS atomizer eye/face wash head, zero

upward velocity stream engineering with even aerated flow. ABS

Atomizer is equipped with flip-off cover to prevent dust

contamination. 1⁄2” inch brass ball valve, Impact corrosion

resistant, with ABS receptor bowl. Inlet supply connection is 1⁄2”

and drain connection is 1 1⁄4”. Hot dipped Galvanized stanchion as

per IS 1239 with epoxy color (green/red/yellow). Flange to

support eye/face wash unit having 4 holes of 10mm.

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg / 12ltr. Per

minute

CONFORMING TO IS: 10592- 1982 revised as per 2018

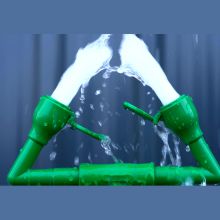

US-GI-5 - Combination Unit

Corrosion-resistant combination shower and eye/face

wash features the latest technology in fluid dynamics

in Unisafe’s WhirlTech ABS drench showerhead, you

get the most consistent distribution of water. Its

superior spray pattern produces the most effective

removal of contaminants in the industry. Combination

unit include push plate which is laser cutted for the

ABS atomizer eye/face wash head, zero upward

velocity stream engineering with even aerated flow.

ABS Atomizer is equipped with flip-off cover to

prevent dust contamination. Laser cutted Pull Rod for

Shower activation. 1⁄2” inch brass ball valve, Impact

corrosion resistant, with ABS receptor bowl. Inlet

supply connection is 1 1⁄4” and drain connection is 1 1⁄4”.

Flange to support eye/face wash unit having 4 holes

of 10mm. Hot dipped Galvanized stanchion as per IS

1239 with epoxy color (green/yellow).

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg

CONFORMING TO IS: 10592- 1982 revised as per 2018

MINIMUM DISCHARGE OF 100 LPM

(BOTH UNITS ACTUATE INDEPENDENTLY)

US-GI-6 - Combination Unit with Foot Pedal

Combination unit include push plate which is laser

cutted and foot operated for the ABS atomizer

eye/face wash head, zero upward velocity stream

engineering with even aerated flow. ABS Atomizer is

equipped with flip-off cover to prevent dust

contamination. The latest technology in fluid dynamics

in Unisafe’s WhirlTech ABS drench showerhead, you

get the most consistent distribution of water. Its

superior spray pattern produces the most effective

removal of contaminants in the industry. Laser cutted

Pull Rod for Shower activation. 1⁄2” brass ball valve,

Impact corrosion resistant, with ABS receptor bowl.

Inlet supply connection is 1 1⁄4” and drain connection is

1 1⁄4”. Hot dipped Galvanized stanchion as per IS 1239

with epoxy color (green/red/yellow). Flange to

support eye/face wash unit having 4 holes of 10mm.

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg

/ 12ltr. Per minute

CONFORMING TO IS: 10592- 1982 revised as per 2018

MINIMUM DISCHARGE OF 100 LPM

(BOTH UNITS ACTUATE INDEPENDENTLY)

US-GI-7 - Stand Alone Shower Head

The latest technology in fluid dynamics available in Unisafe’s

WhirlTec products, you get the most consistent distribution of

water from a drench shower. Its superior spray pattern produces

the most effective removal of contaminants in the industry.

Integral flow control provides of 76 LPM for 15 mins as per IS

10592 standards. Contoured Shape focuses water for faster

washed out. Smaller profile reduces risk of damages in busy

industrial environments. Laser cutted Pull Rod for Shower

activation. 1” brass ball valve, Impact corrosion resistant. Inlet

supply connection is 1 1⁄4”.

RECOMMENDED DESIGNED PRESSURE: 30 PSI / 2Kg / 76ltr. Per

minute

CONFORMING TO IS: 10592- 1982 revised as per 2018

MINIMUM DISCHARGE OF 100 LPM

Maintenance:

Plumbed devices must be tested regularly for a period long

enough to verify operation and to ensure that flushing fluid is

available. This is needed to flush out sediment and microbes, and

to make certain flushing fluid is available at the shower head and

the overall device is in working order.

The purpose of regular testing on plumbed emergency

equipment is to ensure there is flushing fluid supply at the

delivery head of the device and to clear the supply line of any

sediment build-up that could prevent fluid delivery and to

minimize microbial contamination due to standing water.

While not intended the be a full 15-minute flow test, the duration

of this test is dependent on the volume of water contained in the

unit itself and all sections of pipe that do not form part of a

constant circulation system. Water in these sections is static until

a flow is activated by opening a valve. Consideration must also be

given to systems that include mixing valves for hot and cold

water supplies.